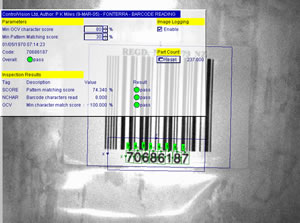

A small job on big cheese: robust barcode reading at Fonterra Whareroa

Fonterra Co-operative Group

Whareroa, New Zealand

- Vision-based ID readers have benefits over traditional laser code readers

- 0% failed read on 65,000 products

- Image logging allows any read failures to be analyzed long after the product has left the scene...

/>

/>

Track & trace applications are one of the fastest growing fields for machine vision technology.

Vision-based ID readers are capable of reading both 1-D codes (barcodes) and 2-D codes such as matrix codes. They cope with wide variations in part presentation, and can read codes in any orientation.

Question: So when would you use a camera, instead of say a laser scanner, for a simple barcode reading task? Answer: when you need a truely robust ID reading solution...

Recently, Fonterra Whareroa asked ControlVision to investigate a problem they were experiencing on 25kg bulk cheese lines: poor read-rates on existing laser barcode scanners. The solution was to install Cognex In-Sight ID readers.

The read success rate was staggering: 65,000 products without a single missread.

While using cameras for barcode reading may seem like hitting a nut with a sledgehammer, as the cost of vision technology comes down there is a trend towards using imaging technology for even these simple ID reading tasks.