Case Studies

Batch verification at Tip Top

Powdered ingredients are a key part of the frozen confectionery manufacturing process. While Powder Projects commissioned a system to boost product quality during mixing, ControlVision to provided a vision system to minimise the potential for human error when adding ingredients.

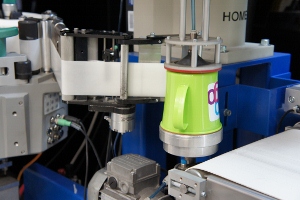

Vision guided robotic labelling at Sistema Plastics

Sistema's new and innovative designs are a major part of their appeal to the market. Recently, this included a range of round soup mugs and other products with rounded sides. This proved to be a major challenge for their existing labelling machine, used on their traditional flat-sided products.

Vision guided robotic clipping at Sistema Plastics

The distinctive plastic clips on Sistema's plastic products are well-known in households in New Zealand, and increasingly around the world. Although the clips had traditionally been attached on the base of a container, when Sistema introduced a new range which featured smaller clips attached to the lid, issues in the manual production process led to the search for an automated solution to lower costs and increase efficiency.

Bringing vision for lights-out packing in the Dairy Industry

GEA Avapac, a specialist powder packing machine supplier and part of the global GEA group, was given a challenge: Fonterra, the largest dairy cooperative in NZ, wanted to jointly develop a solution to reduce or eliminate manual labour from packing rooms. For reasons of both labour savings and food hygiene it made sense to do this – and Fonterra were ready and willing to mount a “technology stretch” project to achieve the goal of what was termed “lights-out packing”. Robotics and Machine Vision has a small but important part to play in the important business of milk powder packing.

Precision Gauging of Plastic Components At Gulf Rubber

More widely known for its gumboots, agricultural and industrial rubber products, Skellerup NZ recently completed a project at Gulf Rubber - a subsidiary that specializes in more esoteric and high-performance plastics. The product, which has been 3 years in development, is a precision moulded dual material plastic bush used in automotive drive train components. The manufacturing quality demands are stringent with Outer Diameter/Inner Diameter (OD/ID) and concentricity tolerances in the order of +/- 0.05mm. Machine vision is used to provide online inspection to ensure that these quality requirements are met.

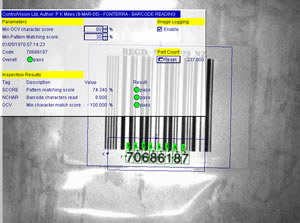

A&RT OCV platform reliably inspects batch and date codes at Kraft

For modern food producers, ensuring that batch and date codes are printed correctly and legibly on perishable goods has become of critical importance. The consequences of getting it wrong can be serious with expensive product recalls and the potential for lost customers. Automation & Robot Technologies (A&RT) or New South Wales have developed a standard date code inspection system designed to be highly flexible, but simple for operators to use. The system can be directly integrated to existing production lines with minimal effort and has the capability to inspect date codes / time stamps and other character inspections in less than 100 ms!

Vision Guided Keg Depalletizing at Canterbury Breweries

Canterbury Breweries (CB) supply draft beer in kegs to many of the South Island's drinking establishments. JMP Engineering installed a Kawasaki palletizing robot to “depalletize’ empty kegs in the plant. In this application a Cognex vision retrofit replaces the underperforming vision system with real tangible performance benefits.

Vision tackles a sweet challenge at NZ Sugar

The iconic Chelsea sugar refinery in Auckland recently solved a long standing problem with their manufacturing process using Machine Vision. With up to 50 types of product ranging in bag material, decoration graphics, size and weight the one Achilles heal of their back-end flexible palletizing system has been reliable identification of product.

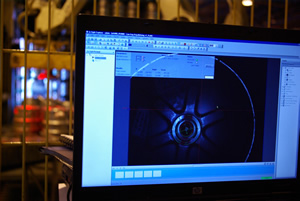

PC-based Vision tackles a core problem on paper rolls

Norske Skog is a world leading producer of paper for newsprint and magazines, with 22 paper mills around the world. The Tasman mill at Kawerau produces over 300,000 tonnes per year, enough for all NZ's newsprint and telephone directory requirements, plus around 25% of Australia’s newsprint needs. Norske Skog were using a manual measurement technique for detecting rolls with excessiveOff Centre Core (OCC). This procedure was both time-consuming and subjective, with different operators achieving different results. ControlVision were approached to provide an automated inspection solution...

Vision Verifies Packaging at TipTop Ice Cream

TipTop is New Zealand's leading ice cream company and produces around 50 million litres of ice cream per year out of facilities in Auckland and Christchurch. A decision to remove barcodes from the top of Ice Cream containers presented a new challenge in production - and a potential food safety concern...

A small job on big cheese: robust barcode reading at Fonterra Whareroa

Track & trace applications are one of the fastest growing fields for machine vision technology. Vision-based ID readers are capable of reading both 1-D codes (barcodes) and 2-D codes such as matrix codes. They cope with wide variations in part presentation, and can read codes in any orientation...

Inspection Vision helps BIC NZ "Compete with Quality"

As New Zealand's manufacturing exporters feel the squeeze of a high NZ dollar, some are choosing to bite the bullet and invest in automation technologies that can improve productivity and reduce their production costs...

Machine Vision Verifies Seals on AMCOR Maxipack bags

AMCOR Australia produce a range of packaging solutions, including large, lined and unlined bags for “bulk products”... Given the complexity of the folding operations, control of quality of the seal is key. For this AMCOR and Innopak relied on ControlVision to come up with a machine vision solution that would integrate into the machine....

Robot Vision Guidance at Hella NZ

Hella asked ControlVision to implement a robot guidance and inspection solution to automate a precision gluing process in the production of custom OEM designed lighting for carmakers.